AUTOMATED ASSEMBLY MACHINES / PRODUCTS

EPE designs and builds custom automated assembly machines to help manufactures grow and evolve in a way that makes sense for their individual operations. From table-top equipment and work-cells to entire turnkey systems, we provide targeted (application specific and product specific) solutions to fulfill our customer’s objectives:

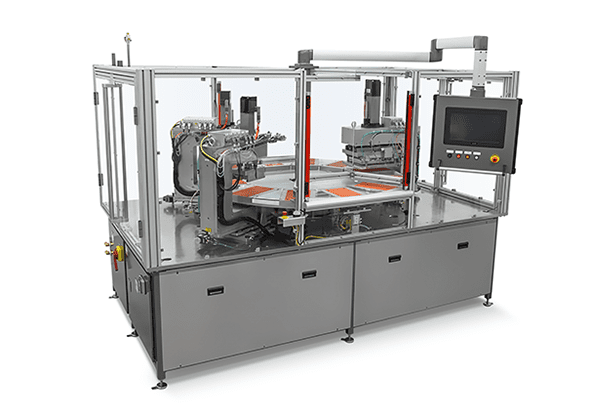

Turnkey Automated Assembly Machines:

EPE designs and builds custom Turnkey Automated Assembly machines for complex products and applications. These systems are capable of systematically sorting, feeding and transferring disparate input materials/components during multiple process steps to produce a finished product. Our fully-automated systems operate continuously, producing products with minimal operator involvement. EPE also builds semi-automated systems with safe-zone operator stations to accommodate loading and manipulating input components when necessary.

Table-Top Equipment & Work-Cells:

EPE designs and builds custom table-top equipment and work-cells for customers that need to automate a single production process or a series of process steps. Table-top equipment and work-cells are capable of increasing the throughput of labor-intensive tasks, while also improving quality and consistency of finished products. Wherever possible we build these units with interchangeable fixtures and tooling to accommodate multiple product sizes and/or product families. In addition, our table-top equipment and work-cells are built with testing functionality when customers need assembly and test capabilities as an integrated process.

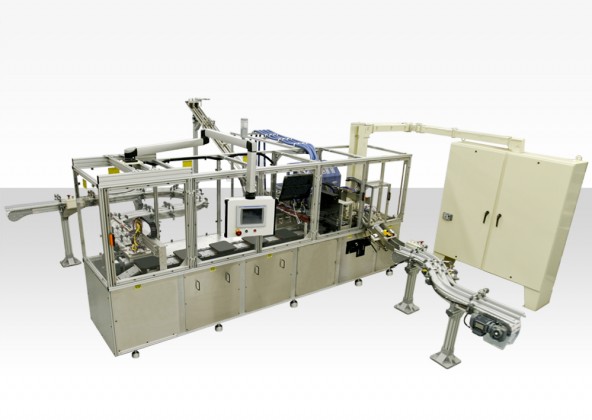

Automated Assembly Machine Platforms:

EPE’s automated assembly platforms, either synchronous or non-synchronous, provide customers with a flexible approach to automation.

- Precision Indexing Conveyors

- Plate Conveyors

- Belt Conveyors

- Power & Free Conveyors

- Indexing Dial Tables

- Robotic Cells

Process Types:

- Bulk Part and Material Feeding

- Bulk Part Sorting and Orienting

- Part Orienting and Registering

- Assembly

- Staking, Sealing, Welding

- Fastening and Screwing

- Gluing

- Dispensing

- Filling

- Marking / Printing

- Labeling

- Testing

- Leak Testing

- Pressure and Force Testing

- Atmosphere Testing

- Continuity Testing

- Inspection

Equipment Technologies:

- Vibratory Bowls, Tables, and Tracks

- Pick & Place Systems

- Robot Systems

- Web/Rollstock Handling Equipment

- Heat Sealing / Staking Equipment

- Ultrasonic Welding Equipment

- Gluing Systems

- Printing / Marking Equipment

- Thermal Transfer Printing Systems

- Ink Jet Printing Systems

- Flexographic Printing Systems

- Gravure Printing Systems

- Laser Marking Systems

- Labeling Equipment

- Liquid and Gel Dispensing Equipment

- Filling Equipment

- Testing Equipment

- Leak Testing Equipment

- Pressure and Force Testing Equipment

- Atmosphere Testing Equipment

- Continuity Testing Equipment

- Inspection Systems

- Vision Inspection Systems

- Contact and Non-Contact Height Detection Sensors

- Weighing Systems

Deciding To Automate:

EPE understands that automating production of a new or existing product is a significant step in manufacturing operations. That’s exactly why an experienced quoting team with applications engineers works closely with our customers to learn and understand the fundamentals of their project. Then we apply our experience and expertise to those project fundamentals, and propose viable solutions for customer’s expectations.

- Knowledge and experience of product or process.

- Current Production Method(s)

- Martial & Component Handling Techniques

- Technical Specifications

- Lessons Learned

- Reasons for automating:

- Production Volume

- Quality / Consistency

- Safety

- Regulatory

- Complicated / Intricate Assembly

- Labor Efficiency

- Performance goals and expectations:

- Rate Requirement (Current and Future)

- Operator / Labor Allocation

- Schedule / Deadline

- Target Budget